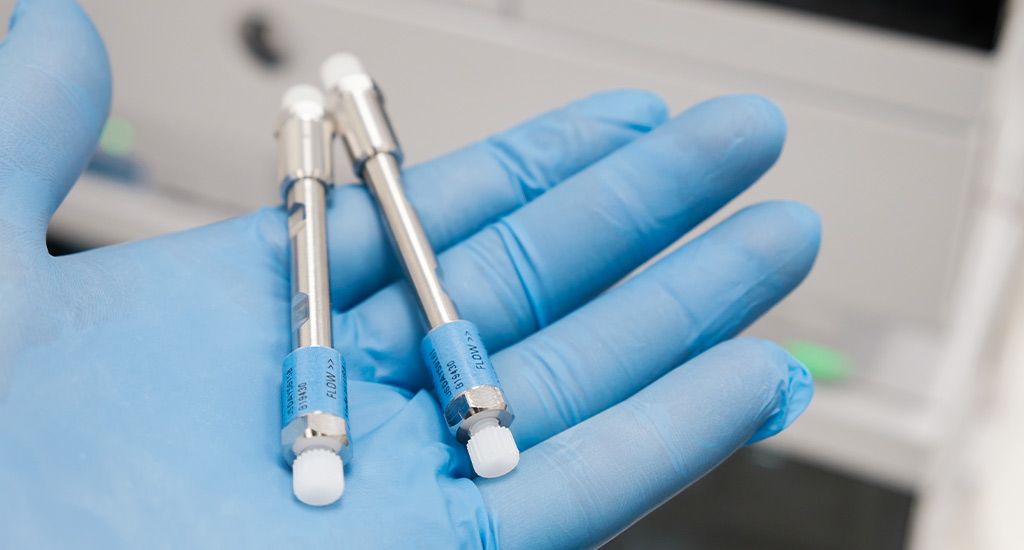

Our corrosion-resistant materials are integral to a diverse range of industrial applications including chemical processing, advanced manufacturing and analytical and testing equipment.

Applications

Successful material solutions require precision, quality, and high customization. We have the expertise to tightly control sizes, surface finishes and properties for your exact critical industrial application including:

Alloys

Our advanced processing capabilities enable us to engineer alloys with exceptional durability and corrosion resistance for industrial applications. Alloys include: